SINGAPORE

IMR Test Labs in Singapore is Asia's premiere materials testing laboratory. We offer high-quality, accredited materials testing services including elemental analysis, metallurgical evaluation, physical/mechanical testing and failure analysis. We can provide support for your manufacturing operations with routine materials checks or can help you solve your toughest materials challenges with a full failure analysis.

We carry a wide range of approvals including ISO/IEC 17025, NADCAP, GE S-400, Pratt & Whitney MCL, and we add more regularly as our client list grows. We are your trusted supplier for fast, accurate materials testing services.

Need testing not listed here? IMR has a wide range of capabilities. We can outsource to one of our other labs if testing is available. Contact us today to discuss your testing needs.

Click here for test request forms that can be faxed, emailed or included when you ship your samples for testing. Be sure to mark if a quote or rush is needed.

GE AEROSPACE CCL (CENTRAL COATINGS LABORATORY)

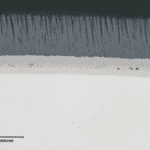

Since 2017, IMR Test Labs - Singapore has been a GE S-459-approved Central Coatings Laboratory (CCL). As a CCL, we provide a GE Aerospace-approved program to train coating laboratory personnel, approve coating testing and evaluation procedures, and certify testing and evaluation through Round Robin testing. Suppliers’ laboratory personnel are required to undergo the CCL training to be certified before testing and evaluating thermal spray coatings to GE Aerospace specifications.

For a full listing of our approved coatings click here GE AIRCRAFT ENGINE-AJ CODE FOR COATINGS (GT193-69562)

More coatings will be added to this list as they get approved by GE Aerospace.

Contact IMR Singapore today at [email protected] for more information or a detailed quote on Round Robin testing or CCL Training.

GE Aerospace Central Coating Laboratory Training Program Thermal Spray Coatings: March 11-15, 2024

IMR Test Labs – Singapore Pte Ltd, a Central Coating Laboratory (CCL) approved by GE Aerospace (GEA) is inviting you to register for the GEA CCL Training Program for the period March 11-15, 2024.

Laboratory personnel are to undergo this training course to be certified before testing and evaluating GE Aerospace Thermal Spray Coatings.

A GE Aerospace-recognized certificate will be issued to participants who have successfully completed and passed the training program.

ANALYTICAL SERVICES

Alpha Case

Case Depth

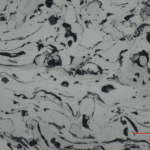

Coatings Evaluations

Decarburization

EDM Surface Evaluations

Effective Case Depth

Failure Analysis

Grain Size

Inclusion Content/Inclusion Rating

Intergranular Attack

Intergranular Oxidation

Machined Surface Evaluations

Macro-etching

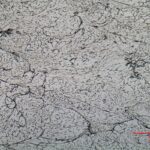

Metallography

Metallurgical Evaluation of Fusion Welds

Micro-etching

Microstructure Evaluation

Plating Thickness, Integrity

Scanning Electron Microscopy

Thermal Spray Evaluation

Weld, Braze, Joining Evaluation

Alloy Verification

Chemical Assay

Combustion Analysis (C &S)

ICP Analysis

Inert Gas Fusion Analysis (O,N,H)

Ion Chromatography Testing for Chlorides, Fluorides and Sulfates

OES Analysis

Raw Material Verification

SEM/EDS Analysis

Bend Test

Bond Strength Testing

Braze, Joining Evaluation

CAAS Welder Qualification

Coating Adhesion (ASTM C633)

Creep and Stress Rupture Testing

Erosion Testing of Coatings

Hardness Testing (Rockwell)

High Temperature Tensile (to 1000°C)

Hydrogen Embrittlement

Lap Shear Strength

Microhardness (Vickers)

Surface Roughness

Tensile

Time-for-Rupture Notch Tension Test (ASTM E292)

ACCREDITATIONS

Click here for our full list of accreditations and certifications

CONTACT INFO

30 Loyang Way #03-16

Singapore 508769

Phone: +65 (6592)-5325

Fax: +65 (6592)-5326

[email protected]

Cage Code: N/A