LOUISVILLE, KY

IMR Test Labs - Louisville is an accredited, independent materials testing laboratory serving clients in the Aerospace, Additive/3D, Energy, Automotive, Medical Device and other high-technology industries. IMR’s Louisville, Kentucky location has earned accreditations from Nadcap and A2LA (ISO 17025) and carries approvals from many major OEMs.

IMR's Louisville, Kentucky laboratory has a long-standing reputation as a failure analysis and metallurgical lab. With thousands of completed failure investigations and litigation cases completed our metallurgical staff has demonstrated ability to get you the answers you need.

We have expanded our services in the areas of chemical analysis, corrosion testing, mechanical testing, cleanliness testing and more in order to better meet your needs. Our lab now offers cleanliness testing to the medical device industry; xrd analysis for phase identification, powder diffraction and % crystallinity; salt spray testing and temperature & humidity exposure, just to name a few.

We have also created efficiencies in our login, sample preparation and testing processes which improves our capacity for handling high-volume, routine chemical, mechanical and metallurgical analyses. If you have routine work such as material checks or process checks, ask us about volume pricing.

Click here for test request forms that can be faxed, emailed or included when you ship your samples for testing. Be sure to mark if a quote or rush is needed.

To learn more about IMR's Louisville, KY testing laboratory, call us or contact us today. We look forward to working with you!

PIPELINE INTEGRITY TESTING

IMR Test Labs is a well-equipped and experienced pipeline materials testing resource. We've helped numerous regional, national and international petro-chemical production and transmission companies answer questions specifically related to pipeline material properties.

IMR has the mechanical, chemistry and metallurgical expertise to help operators apply the test data to decisions about future pipeline maintenance plans. Our clear, concise reports contain the critical analyses to insure compliance with 49CFR, Part 192- the requirement that operators have full knowledge of assets operating in High Consequence Areas (HCA).

ANALYTICAL SERVICES

Alloy Chemistry

C, S, H, O, N Analysis

Chemical Resistance Testing

Cleanliness Testing

Coating Weight

Contaminant/Corrodent ID

Density of Powdered Metals

Filler Content Analysis

FTIR Analysis

Halogen Analysis

Ion Chromatography

Metallic Material Verification

OES Analysis

On-Site PMI Testing

Polymeric Material Verification

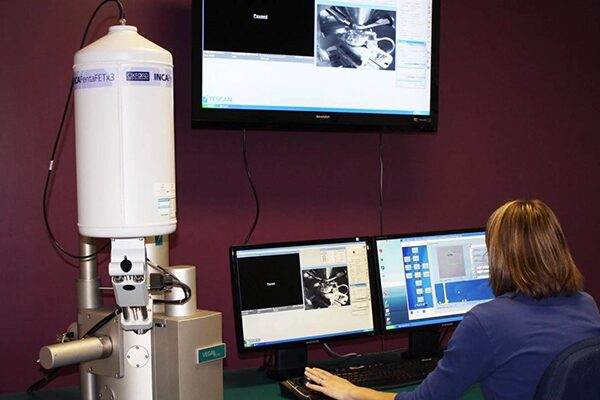

SEM-EDS Analysis

Compound Morphology

Identification of Unknown Powders

Percent Crystallinity

Phase Identification

Powder Diffraction

Salt Spray Testing

Humidity & Water Fog Testing

CASS Testing

Temperature & Humidity Testing

3 & 4 Point Bend Testing

Certified Welder Inspections

Creep and Stress Rupture Testing

Flattening

Hardness (Rockwell, Brinell)

Heat Treatment (furnace to 2100ºF)

Hydrogen Embrittlement (F519)

Tensile Testing

Welder & Procedure Qualification

Case depth

Decarburization

Failure Analysis

Fractography

Grain size

Inclusion rating

Intergranular attack

Intergranular oxidation

Light microscopy

Macro, micro & SEM photography

Microhardness (Knoop, Vickers)

Microstructure

Particle analysis (ID, size)

Plating & coating analysis

Plating thickness

Porosity of metal

SEM Analysis

Welder & Procedure Qualification

ACCREDITATIONS

Click here for our full list of accreditations and certifications

CONTACT INFO

4510 Robards Lane

Louisville, KY 40218

Phone: (502) 810-9007

Fax: (502) 810-0380

[email protected]

HR Contact: [email protected]

Cage Code: 6XHT3