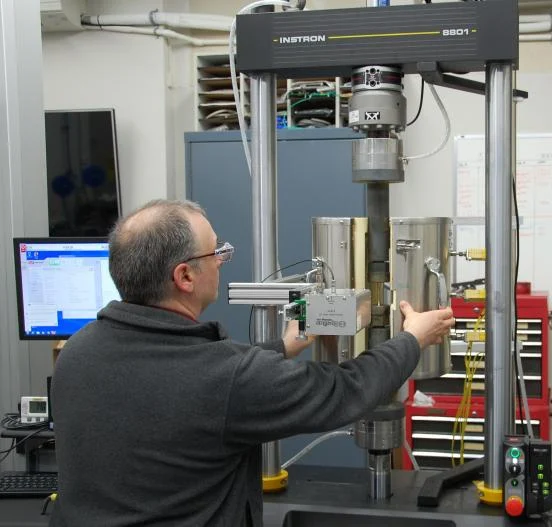

High Temperature Fatigue Testing Services

HIGH-TEMPERATURE FATIGUE TESTING REPLICATES OPERATING CONDITIONS

In response to increased demand for high-temperature fatigue testing from the aerospace, automotive and power generation industries, IMR Test Labs-Ithaca has invested in several dedicated High-Temperature Fatigue testing units. Our lab is compliant with Nadcap testing standards, and we follow the ISO 12016 and ASTM E606 standard practice specs for strain controlled fatigue testing, used for simulating mechanical loading into the plastic region.

The test frame's ability to expose the test specimen to temperatures up to 1800°F can replicate the service conditions experienced by turbine blades in gas engines, power generating plants and jet engines.

HIGH-TEMPERATURE FATIGUE TESTING CAPABILITIES

- High capacity loading frame maximizes lateral and axial stiffness during reverse stress testing.

- All-electric actuator delivers precise slow speed control with virtually silent operation and no hydraulic infrastructure requirements.

- AlignPRO alignment fixture and supporting software are provided as standard to ensure precision loadstring alignment.

- Three zone furnace with cascade control of specimen temperature with optimized temperature gradient.

- Dedicated LCF3 software suite provides streamlined test setup and analysis of hysteresis loops, plastic strain measurement and common LCF calculations.

- The Instron LCF system are fully integrated and are supplied ready to test, meeting all appropriate international standards.

Click here to request a quote, or click on the button below for more information on IMR's high-temperature fatigue testing capabilities.

Adhesion (Peel) Testing

Bend Testing

Bond Strength Testing

Charpy Impact Testing (-320°F to 450°F)

Climbing Drum Adhesion of Sandwich Composites

Coating Adhesion

Coating Shear Fatigue

Coefficient of Thermal Expansion by TMA

Composite Testing (Fiber Reinforced)

Compression Set

Compressive Properties

Core Shear Properties of Sandwich Construction by Beam Flexure

Creep and Stress Rupture Testing

DMA (Dynamic Mechanical Analyzer)

Ductility

Elastic Modulus

Fatigue Testing

Filled Hole Tension & Compression

Flattening

Flat-wise Tensile Testing

Flexural Properties

Floating Roller Peel Strength

Fracture Mechanics

Gel Time

Hardness (Rockwell, Brinell, Durometer, Shore, Barcol, Knoop, Vickers, Macro Vickers)

Heat Aging

Heat Deflection by TMA

Heat Treatment (furnace to 2100°F)

Hydrogen Embrittlement

Hydrostatic Pressure

Indentation Toughness

Interlaminar Shear

Jominy Hardenability

Lap Shear Testing

Machining & Specimen Preparation

Materialography

Modulus of Rupture (MOR)

n-Value (Strain Hardening Exponent)

Open Hole Tension and Compression

Pipeline Integrity Testing

r-Value (Plastic Strain Ratio)

Residual Strength of Composites After Impact

Rotating Beam Fatigue

Shear Testing of Rivets to ASTM B565, Single/Double

Short Beam Strength

Shot Peen Qualification

Single-Edged Notched beams (SENB)

Slow Strain Rate (G129)

Specimen Conditioning

Strain Gaging

Surface Roughness (ANSI/ASME B46.1)

T Peel Strength

Tear Resistance of Films & Sheeting

Tear - Rubbers & Elastomers

Tensile Testing

Torsional and Axial Fatigue (200 lb)

Tube Testing (Tensile, Flare, Hydrostatic)

Welder & Procedure Qualification

Wire/Spring Testing (Wrap, Coil, Bend)

Young's, Tangent and Chord Modulus (Room Temperature)

RELEVANT ACCREDITATIONS

Click here for a complete list of accreditations and certifications for all IMR Test Labs locations.