ICP-MS ANALYSIS

ICP-MS analysis (Inductively Coupled Plasma / Mass Spectrometry) is a very sensitive elemental testing technique that provides very low detection limits for most elements present in a sample.

Low-level elements are identified for the following:

- Process solutions and chemical baths

- Ion release elements in medical simulation solutions

- Heavy metals in medical applications and wear debris testing

ICP-MS ANALYSIS IDENTIFICATION OF ELEMENTAL COMPOSITION

- Aluminum

- Iron-Based Metal

- Nickel

- Cobalt

- Copper

- Titanium Alloys

- Polymers

- Plastics

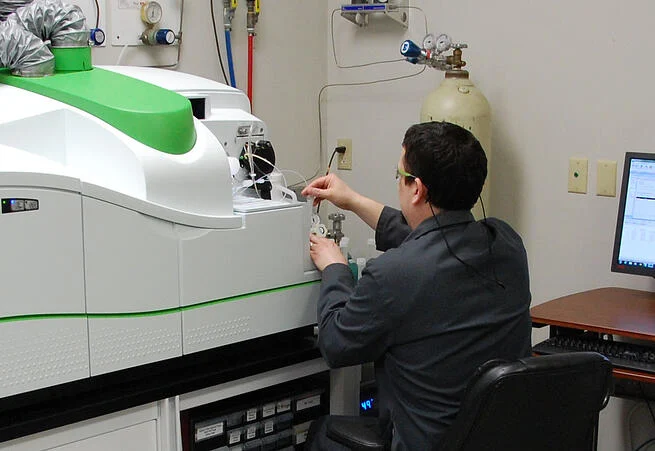

How an ICP-MS Test is Performed

Samples need to be in solution form, which requires solid samples to be dissolved. Test specimens are digested with a combination of acids appropriate for the chemical composition testing of the alloy.

The ICP-MS instrument measures the mass-to-charge ratio of a high-temperature plasma sample that becomes ionized.

The instrument is calibrated per use, using calibration standards designated by laboratory personnel, such as Quality Management. The calibration standards are matrix matched (Ni, Fe, Ti, etc.) to the samples being analyzed. Elements to be analyzed are added to calibration standards using NIST traceable solution standards. Calibration curves usually consist of 3-6 calibration standards.

To find out more about IMR's ICP-MS capabilities, click the Contact Us button below, or click the Request A Quote button if you're ready.

Alloy Chemistry

Antimony Analysis (ICP)

Cadmium Analysis (ICP)

Carbon, Sulfur, Hydrogen, Oxygen & Nitrogen

Contamination ID

Contaminant/ Corrodent Analysis

Filler/Additive Analysis

FTIR

Halogen Analysis (IC)

Heavy Metals Analysis

Hex Chrome (UV-VIS)

ICP-AES Analysis

ICP-MS Analysis

Impurities Analysis

Ion Chromatography

Material Certification

Metal Purity

OES Analysis

On-site PMI

PMI Testing (Positive Material ID)

Particle Size Analysis

Percent Crystallinity

pH

Polymer Testing

Powder Diffraction

Powdered Metal Analysis

Precious Metal Assay

Quantitative Analysis

Resistivity (ASTM D1125)

SEM-EDS

Semi-Quantitative Analysis

Trace Element Analysis

Unknown Alloy Identification

Unknown Material Identification

XRD Analysis

XRF Analysis

ICP-MS TESTING STANDARDS FOR THE AEROSPACE INDUSTRY

- AMS 2280

- AMS 5662

- AMS 5663

- AMS 5706

- ASTM E 2823

- GE P29A-AG100

- and more...

ICP-MS FAQ's

As little as a few milligrams are needed for an ICP-MS test; however, the testing is typically done in batches, with several samples tested concurrently.

The typical process of an ICP-MS test is completed within a few hours. Most samples can be tested within two days of receipt.

ICP analysis generates results from the measure of wavelengths of light emitted from an aerosolized solution burning in plasma. ICP-MS analysis generates results from an ionized solution by assessing the mass-to-charge ratio. An ICP analysis can be performed on both solid and liquid samples, however ICP-MS is performed on liquid samples, and solid samples need to be dissolved in an appropriate acid prior to testing.

ICP-MS analysis cost varies per material and the quantities tested. For more information, request a quote.

RELEVANT ACCREDITATIONS

Click here for a complete list of accreditations and certifications for all IMR Test Labs locations.