Manufacturers supplying the transportation industry require extensive quality-control testing services to deliver high-quality finished vehicles that meet the demands of the personal and commercial transportation markets.

IMR offers a wide range of lab testing and analytical services for automotive, shipping, military, material handling, and mass transit applications.

IMR Test Labs performs routine production checks, support for R&D efforts, and comparative analyses of different lots/materials/suppliers. Should problems arise, we can also investigate failed metallic and polymer/composite/plastic parts.

With the explosive growth of EV (Electric Vehicles) in both personal and commercial transportation, IMR is well-positioned to apply our extensive lab experience in testing fuel-driven car, truck, bus, and train parts to the specialized needs of EV material and component manufacturers.

Learn more about our analytical services for the automotive industry below, or request a quote today!

EV/Transportation Industry Testing- Corrosion

IMR Test Labs have extensive corrosion testing expertise. We have a variety of chambers and environments to fit your needs. From standard B117 salt spray exposure and cyclic corrosion, to domestic and European OEM requirements, we have performed many hours of accelerated weathering testing for automotive clients.

EV/Transportation Industry Testing- Standards

IMR Test labs have rigorous standards for transportation testing methods from the following internationally accredited standards agencies:

- ASTM

- American Society for Testing and Materials

- MIL

- United States Defense Military Standard

- SAE

- Society of Automotive Engineers

- ISO

- International Organization for Standardization - 16232 / VDA 19 - per ISO this standard is for technical cleanliness of road vehicles

EV/Transportation Industry Testing- Routine Panel

Panel refers to a piece of an automobile that is routinely tested in order to predict outcomes and leverage ongoing manufacturing decisions. Panel specimens can be metal, a particular coating or type of paint. Routine testing offers insight based on data that is continuously collected over a period of time, in order to analyze potential changes or discrepancies in material properties.

EV/Transportation Industry Testing- OEM Specifications

IMR Test labs have rigorous standards for transportation testing methods from the following internationally accredited standards agencies:

GM/GMW

Validation testing in accordance with GM GMW3097 must be performed at a laboratory that has received recognition through the Automotive EMC Laboratory Recognition Program (AEMCLRP)

DBL

The Daimler-Benz company standard DBL 5404 describes the requirements for plastic parts of the vehicle interior.

DIN

DIN standard 75201 is a method developed by the German Institute for Standardization that enables vehicle material manufacturers to test the level of condensing and/or evaporation of volatile compounds.

Ford

Ford Standards Testing

GS

HES

Honda Standards Testing

TL

VDA

VDA 270 is a widely used method in the automobile industry. This test evaluates odors emitted from parts and materials inside the car under the influence of temperature and climate.

VCS

Vapor control system

EV/Transportation Industry Testing- Cleanliness

Whether one-time, or routine, we have performed cleanliness testing to a number of manufacturer specifications that cover internal cleanliness of closed systems, surface cleanliness and ionic contamination. We can work with water, or a multitude of solvents.

Whether you manufacture tractors or trucks, send us your specification and we'll see how we can help you.

EV/Transportation Industry Testing- Failure Analysis

IMR's experts have extensive failure analysis and litigation support experience with the automotive industry. As one of IMR's key markets from the beginning, our automotive clients have trusted us to provide thorough, concise and accurate root cause investigations of failed parts for over a decade.

With state of the art equipment and the support of our other departments, the failure group can get you the answers you need to solve your toughest challenges on nonmetallics, metals and contaminants.

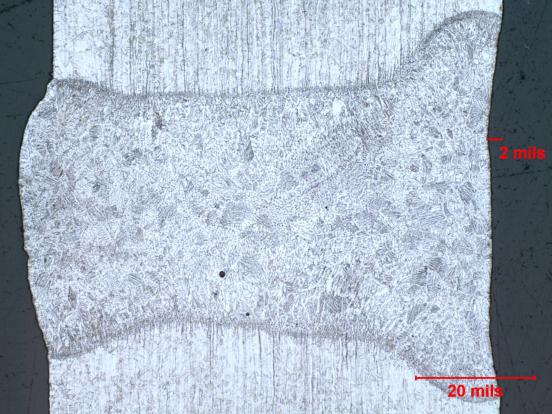

EV/Transportation Industry Testing- Welding Procedure Qualification and Welder Certification

With weld qualification experts at all of our labs, IMR can provide the welder & procedure qualification testing you need. From testing raw materials, to qualifying new welders, or analyzing a failed weld, we have the staff, experience and equipment you need. Chemical analysis, mechanical testing, metallurgical analysis and qualification packages are available at all of our labs in the US and Asia.

EV/TRANSPORTATION INDUSTRY ANALYTICAL SERVICES

CASS Testing

Chip Resistance (Gravelometer)

Cyclic Corrosion

Humidity

Salt Spray Testing

Temperature & Humidity

UV Exposure / QUV

Bond Strength

Coating Adhesion

Charpy Impact

Fatigue

Flexural

Hardness

Tensile

Weld Inspection

Contaminant Identification

Corrosion Failure

Litigation/Expert Witness Services

Nonmetallic Failure Analysis

Structural Failures

Warranty Returns

Case Depth

Contamination/FOD Identification

Defect Analysis

Fusion Weld Inspections

Hydrogen Embrittlement

Microhardness (Knoop, Vickers, Macro Vickers)

Microstructure

Plating Thickness

PPAP

Resistance Weld Inspections

Weld Testing

Alloy Chemistry

Cleanliness Testing

Coating Weight

ELV Testing

Hazardous Substances Testing

Hexavalent Chromium

Material Verification

Trace Element Analysis

Adhesion

Ash Content

Chemical Resistance of Coatings

Chemical Exposure of Plastics

Composites Analysis

Compressive Properties

Contaminant Analysis

Failure Analysis

Flammability (UL94, FMVSS 302, ISO 3795, SAE J369, ASTM D5132)

Flexural Properties

Fluid Aging

Gardner Impact

Gloss (ASTM D523, D4039)

Hazardous Substance

Heat Aging

Material ID/Verification

Paint Analysis

Tensile

ACCELERATED WEATHERING & CORROSION TESTING

IMR's Ithaca, NY and Louisville, KY labs have extensive corrosion testing capabilities. One of our particular areas of expertise is automotive corrosion specifications.

We have a variety of chambers and environments to fit your needs. From standard B117 salt spray exposure and cyclic corrosion, to domestic and European OEM requirements, we have performed many hours of accelerated weathering testing for automotive clients.

In addition to ASTM, MIL, SAE and ISO methods, some of the OEM specifications we have tested to include GM/GMW, DBL, DIN, Ford, GS, HES, TL, VDA and VCS. Send us your specification today and we'd be happy to review it.

Have monthly panel testing? Contact us for special volume pricing.

CLEANLINESS TESTING

Whether one-time, or routine, we have performed cleanliness testing to a number of manufacturer specifications that cover internal cleanliness of closed systems, surface cleanliness and ionic contamination. We can work with water, or a multitude of solvents.

Whether you manufacture tractors or trucks, send us your specification and we'll see how we can help you.

FAILURE ANALYSIS

IMR's experts have extensive failure analysis and litigation support experience with the automotive industry. As one of IMR's key markets from the beginning, our automotive clients have trusted us to provide thorough, concise and accurate root cause investigations of failed parts for over a decade.

With state of the art equipment and the support of our other departments, the failure group can get you the answers you need to solve your toughest challenges on nonmetallics, metals and contaminants.

WELDING PROCEDURE QUALIFICATION AND WELDER CERTIFICATION

With weld qualification experts at all of our labs, IMR can provide the welder & procedure qualification testing you need. From testing raw materials, to qualifying new welders, or analyzing a failed weld, we have the staff, experience and equipment you need. Chemical analysis, mechanical testing, metallurgical analysis and qualification packages are available at all of our labs in the US and Asia.

We can analyze welds to a multitude of specifications including ABS, AMS, API, ASME, AWS, EN, ISO, SAE and more. We'd be happy to review your specification and see how our weld testing group can help you.